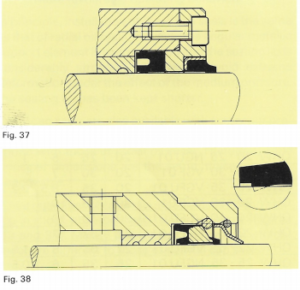

Kaco BILIP—H seal scraper elements serve the purpose of sealing rods in hydraulic equipment. They have two simultaneous functions — that is to say, sealing and scraping. In comparison with the rod seals with U-rings and scrapers usually used in the past (figure 37), BILIP-H seal scraper elements (figure 38) exhibit the following advantages:

- These can be replaced from the outer side of the equipment

- Low space requirements

- Low friction

- Long service life

Technical data:

Pressure range ≤ 200 bar

Permissible sliding speed ≤ 0.3 m/s

Tolerances

dynamic (rod) H9

static (housing) H10

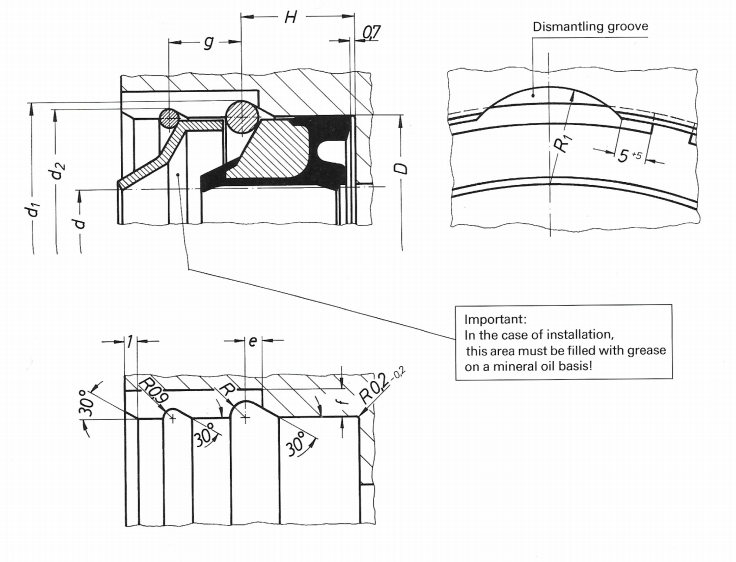

The main features of BILIP-H elements are the V-type sealing lip design and the special shape of the Vulcanized metallic support element. The contact surface of the seal on the rod is limited to the necessary minimum for good seal functioning and long service life. Therefore, the frictional forces are lower than those found when a U-ring is used. As a result of the shape and dimension of the metallic insert, in comparison with a

seal with a U-ring, the gap between the rod and housing no longer plays any role. Therefore, it is possible to support the rear of the BILI P-H seal scraper element in its location hole in the housing by means of a round wire circlip (German standard DIN 7993, type B). Regarding the necessary pressing-in tools please contact our engineering department.

The maximum tension force of the V-type sealing lip is directly in the area of the sealing edge (refer to the description on page 4, figure 3). Asa result of this, the formation of a liquid wedge is more or less suppressed and a maximum amount of sealing is achieved. In order to protect the rubber scraper of the BILIP element in extreme conditions, an additional QY metal scraper can be provided (refer to the table of dimensions on page 35). This is also held by means of a round-wire circlip. The space between the metal scraper and the BILIP element is filled with grease.

During the installation of BILIP-H seal scraper elements, ensure that the rubber cam of the sealing ring, which is provided to prevent displacement, lies between the ends of the round-wire circlip. In this case, the arc-shaped dismantling groove which runs in an axial direction can serve as an orientation aid (figure 39).

In order to remove the BILIP-H sealing ring, the round wire circlip must be turned in a circumferential direction with the aid of a screwdriver until the dismantling groove is completely covered (illustration on the top right-hand corner of page 35). The dismantling groove is provided to aid removal by means of a screwdriver from the retaining groove of the round wire circlip (figure 42). The BILIP-H sealing ring is removed by means of slight pressure action or by removing the piston rod.

| Item number BILIP element | d | D | H | d1 | e | R | f | R1 | Item numbers of metal scrapers | d2 | g | |

| QHLH 8.18 VGUO1 | 8 | 18 | 9,2 | 19,6 | 0,9 | 0,9 | 1,5 | 4 | QY 8.18 | 19,6 | 4,5 | |

| QHLH 10.20 VGUO1 | 10 | 20 | 9,4 | 22 | 1,1 | 1,1 | 1,8 | 4 | QY 10.20 | 21,6 | 4,7 | |

| QHLH 12.22 VGUO1 | 12 | 22 | 9,4 | 24 | 1,1 | 1,1 | 1,8 | 4 | QY 12.22 | 23,6 | 4,7 | |

| QHLH 14.24 VGUO1 | 14 | 24 | 9,4 | 26 | 1,1 | 1,1 | 1,8 | 4 | QY 14.24 | 25,6 | 4,7 | |

| QHLH 16.26 VGUO1 | 16 | 26 | 9,4 | 28 | 1,1 | 1,1 | 1,8 | 5 | QY 16.26 | 27,6 | 4,7 | |

| QHLH 18.28 VGUO1 | 18 | 28 | 9,4 | 30 | 1,1 | 1,1 | 1,8 | 5 | QY 18.28 | 29,6 | 4,7 | |

| QHLH 20.30 VGUO1 | 20 | 30 | 9,4 | 32 | 1,1 | 1,1 | 1,8 | 5 | QY 20.30 | 31,6 | 4,7 | |

| QHLH 22.32 VGUO1 | 22 | 32 | 9,7 | 34,5 | 1,4 | 1,4 | 2 | 7,5 | QY 22.32 | 33,6 | 5 | |

| QHLH 25.35 VGUO1 | 25 | 35 | 9,7 | 37,5 | 1,4 | 1,4 | 2 | 7,5 | QY 25.35 | 36,6 | 5 | |

| QHLH 28.38 VGUO1 | 28 | 38 | 9,7 | 40,5 | 1,4 | 1,4 | 2 | 7,5 | QY 28.38 | 39,6 | 5 | |

| QHLH 30-40 VGUO1 | 30 | 40 | 9,7 | 42,5 | 1,4 | 1,4 | 2 | 7,5 | QY 30.40 | 41,6 | 5 | |

| QHLH 32.42 VGUO1 | 32 | 42 | 9,7 | 44,5 | 1,4 | 1,4 | 2 | 7,5 | QY 32.42 | 43,6 | 5 | |

| QHLH 36.46 VGUO1 | 36 | 46 | 9,7 | 48,5 | 1,4 | 1,4 | 2 | 7,5 | QY 36.46 | 47,6 | 5 | |

| QHLH 40.50 VGUO1 | 40 | 50 | 9,7 | 52,5 | 1,4 | 1,4 | 2 | 7,5 | QY 40.50 | 51,6 | 5 | |

| QHLH 45.55 VGUO1 | 45 | 55 | 10,3 | 58,2 | 1,8 | 1,8 | 2,5 | 10 | QY 45.55 | 56,6 | 5,4 | |

| QHLH 50.60 VGUO1 | 50 | 60 | 10,3 | 63,2 | 1,8 | 1,8 | 2,5 | 10 | QY 50.60 | 61,6 | 5,4 |

Beoordelingen

Er zijn nog geen beoordelingen.